Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

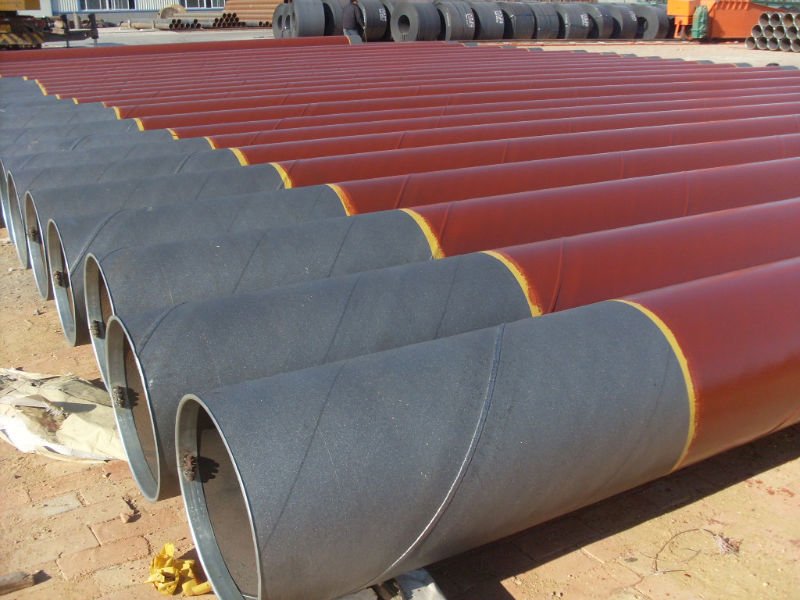

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

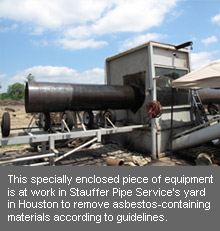

Steel Pipe Rehabilitation Coating Steel Pipeline,Anti-corros

Steel Pipe Rehabilitation

Most pipelines have some sort of coating. If proper procedures are undertaken, the coatings can be removed on location or the removed pipeline can be transported to a cleaning yard. Responsible recovery crews are environmentally certified and educated to handle coating waste in case the coating turns out to be hazardous.

After the coating is removed, the pipe is checked for bends, bows, dents, and dings. Roundness and straightness is also to be ascertained. Pipe should be separated at this stage to determine the better pipe that might be ready to ship to a customer or that might need additional attention. No matter how competent an operator might be, damages will occur, and externally the pipe can be dented or dinged with the track hoe forks or shoe during the removal process.

Sometimes the pipe could be bowed intentionally when laying and need to be straightened. Customers want round and straight pipe, and it is much more economical to load and transport straight pipe. Beveling of each end where the pipe was cut during removal is necessary if the pipe is to be re used as line pipe. Some pipeline recovery crews may be able to rehabilitate excavated pipelines at the removal site by using portable de-denters, pipe straighteners, beveling machines. It is best to reduce the trucking and handling of the pipe as much as possible and perform pipe rehabilitation on-site. Otherwise, there are pipe service yards in various parts of the country that have the expertise and equipment to handle most jobs. If the pipe coating has not been severely damaged beyond repair, the pipe will go directly to a coating facility or threading facilities depending on the intended use for the excavated pipe.

NAME:spiral steel pipe

Min order: 10 TONs

Standard: API 5L,ASTM A210-1996 JIS G3455-2005

OD:219-3500

NAME: steel pipe with API standard

Standard: API 5L,ASTM A210-1996 JIS G3455-2005

|

Product name |

Coating Steel Pipe(Anti-corrosion, coated, lined steel pipes) |

|

Out diameter |

21.3mm-3048mm, 1/2”-120” |

|

Wall Thickness |

1.8mm-22mm, SCH 5S, SCH 10S, SCH10, SCH20, SCH30, SCH40S, STD, SCH40, SCH60, SCH80S, XS, SCH80, SCH100, SCH120, SCH140, SCH160, XXS etc. |

|

Coating Material |

FBE Liquid Epoxy Paint PE, 2PE, 3PE (Polyethylene); 2PP, 3PP (Polypropylene) Epoxy Coal Tar; Epoxy Coal Asphalt; Cement Mortar Lining; Polyurethane Foam Insulation Polyurethane Paint Blue 3PE/ FBE Interzone 954 Paint Heat/ Cold Shrinkable Tapes Denso Tapes Plastic/ Rubber Lining |

|

Standard |

DIN30670, CAN/CSA-Z245.21-M92, NFA49710, ISP-G-TP-335, SY/T0413-2002, DIN30678, DIN30671,CAN/CSA-Z245.20-M98, Q/CNPC38-2002, SY/T0315-2005, AWWA C210, SY/T0457-2002, ANSI/AWWA C222-2008, CJT114-2000, SY/T0447-96, CJ/T 120-2008 |

|

Quality grade |

First class, prime, newly produced, secondary , stock etc. |

|

End |

Plain end, beveled, spigot & socket joint, cut square, grooved, threaded and coupling, etc. |

|

Packing |

Small sizes packed by steel strips into bundles, big sizes in loose pieces; can be packed as customers’ special requirements |

1.the diameter of Spiral steel pipe is from φ219 to φ2850mm and wall thickness is from 5mm to 25mm. the brand of our product is Cangzhou.

2.Our product comply with the standard of SY/T5037-2000, GB/T9711.1-1997 and API SPEC 5L, the material can be Q235AB, 16Manganese and X42-X70 grade plate.

3.The products are widely used in the long-distance transmitting pipelines of natural gas, petroleum, chemical industry, power, heat power and water source etc.

4.I promise you will get the most competitive price from us here.

New Update Pipe List

-

Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production.

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe .

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe