Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

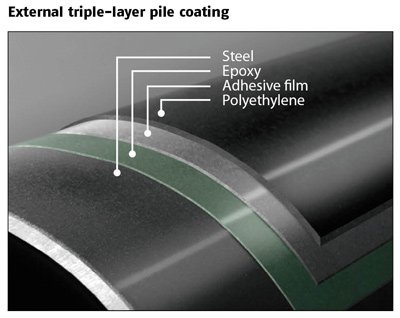

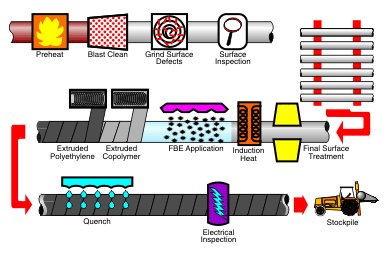

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

3PE Coated Line Pipe

API 5L PSL1/PSL2 Gr.B/X42/X52/X56/X60/X65/X70/X80 3PE/FBE Coated Line Pipe

OD: 2"-30",

WT:0.250"-4"

L:random,fixed,SRL,DRL

Application

Used for construction of long distance pipelines for combustible liquids and gases, nuclear station pipelines, heating system pipelines, general-purpose pipelines, vessels manufacturing, mechanical engineering and instrumental engineering.

COATINGS

External Coating / Wrapping to international standards such as AWWA, BS, JIS

• Coal tar enamel / Bitumen

• Polyethylene tape wrapping

• Coal tar epoxy coating

• Polyurethane coating

Internal Coating / Lining conforming to AWWA, BS, JIS such as

• Liquid epoxy coating

• Cement lining

• others

Test Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield

strength, Elongation), Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc), Exterior Size Inspection

Mill Test Certificate EN 10204/3.1B

WELDED PROCESS

ERW HFI EFW

Outer Diameter 6mm-610mm (1/16"-24")

Wall Thickness 0.3mm-22mm

Length 0.5mtr-20mtr

LSAW DSAW

Outer Diameter 219mm-1820mm

Wall Thickness 5.0mm-50mm

Length 6mtr-18mtr

SAW SSAW

Outer Diamter 219.1mm - 4064mm (8" - 160")

Wall Thickness 3.2 mm - 40mm

Length 6mtr-18mtr

End

square ends (straight cut saw cut and torch cut);

beveled for welding (All line piping is square cut to the tolerance specified and bevelled to ANSI B16.25. An angle of 30º (-0º +5º) and a landing of 16 mm ±08 mm is applied. Schedule 160 material is supplied without bevelling.)

Surface Lightly oiled Hot dip galvanized Electro galvanized Black Bare Varnish coating/Anti rust oil Protective Coatings (Coal Tar Epoxy Fusion Bond Epoxy 3-layers PE)

Test Chemical Component Analysis Mechanical Properties (Ultimate tensile strength Yield

strength Elongation) Technical Properties (Flattening Test Bending Test Hardness Test Blow Test Impact Test etc.) Exterior Size Inspection Hydrostatic Test(The standard pressure is limited to 207 MPa (3000 psi)) X-ray Test.

Mill Test Certificate EN 10204/3.1B

Third party inspection SGS BV Lloyds etc.

上一篇:BUTT WELDED BEND

New Update Pipe List

-

API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production.

Hot Click PRO

-

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a.

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe