Seamless steel pipe

Seamless steel pipe- pipeline

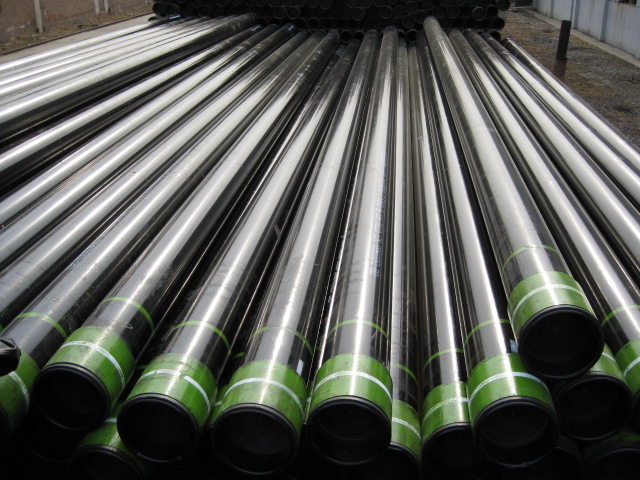

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

API PIPE - LINE

I. API SPEC 5L

Specifications Ranges:

OD: 1/2"-48" (21.3mm-1219mm)

WT: SCH10-SCH80 (0.5mm-40mm)

Material Standard:

PSL 1: A25, A, B, X42, X46, X52, X56, X60, X65, X70

PSL 2: B, X42, X46, X52, X56, X60, X65, X70, X80

Applications:

For the purpose of transportation of gas,water,oill

in oil&gas industry.

II. API SPEC 5CT (OCTG)

Specifications Ranges:

OD: 1.05"- 20" (26.67mm-508mm)

WT: (2.87mm-23mm)

Material Standard:

J55, K55, N80, L80, P110, Q125, ect

LTC, STC, BTC, VAM, EUE, NUE, ect

Applications:

Tubing is used in extracting petroleum & natural

gas.

Casing pipe serves as wall of well.

Destructive & Non-Destructive Testing

Hydrostatic Testing----- 100% of pipe shall be tested at a pressure

specified in above specification.

PSL-1 (NDT) ----- Weld seam of each pipe shall be tested by online

Eddy Current Test.

PSL-2 (NDT) ------ Steel skelp and weld seam shall be tested by

Ultrasonic Test (after hydro test)

1.Flattentig 1. Flatten upto 1/2 of OD (no crack in weld)

2.Flalten upto 1/3 of OD (no crack or breaks other than in weld)

3. Full Flattening (No Lamination or Burnt Metal)

Chemical composition of our API 5L line pipeee

| Standard | Product Specification Level | Steel grade | Chemical composition, % | ||||||||

| C | Mn | P | S | Si | V | Nb | Ti | CEpcm | |||

| API 5L | PSL 1 | L210 or A | ≤ 0.22 | ≤ 0.90 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 |

| L245 or B | ≤ 0.28 | ≤ 1.20 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| L290 or x42 | ≤ 0.28 | ≤ 1.30 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| L320 or X46 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| L360 or X52 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| L390 or X56 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| L415 or X60 | ≤ 0.28 | ≤ 1.40 | ≤ 0.030 | ≤ 0.030 | - | - | - | - | ≤ 0.25 | ||

| PSL 2 | L245Ror BR | ≤ 0.24 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | c | c | ≤ 0.04 | ≤ 0.25 | |

| L290R or X42R | ≤ 0.24 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | ≤ 0.06 | ≤ 0.05 | ≤ 0.04 | ≤ 0.25 | ||

| L245N or BN | ≤ 0.24 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | c | c | ≤ 0.04 | ≤ 0.25 | ||

| L290N or X42N | ≤ 0.24 | ≤ 1.20 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | ≤ 0.06 | ≤ 0.05 | ≤ 0.04 | ≤ 0.25 | ||

| L320N or X46N | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | ≤ 0.40 | ≤ 0.07 | ≤ 0.05 | ≤ 0.04 | ≤ 0.25 | ||

| L360N or X52N | ≤ 0.24 | ≤ 1.40 | ≤0.025 | ≤ 0.015 | ≤ 0.45 | ≤ 0.10 | ≤ 0.05 | ≤0.04 | ≤0.25 | ||

| L390N or X56N | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | ≤ 0.45 | ≤ 0.10 | ≤ 0.05 | ≤0.04 | ≤ 0.25 | ||

| L415N or X60N | ≤ 0.24 | ≤ 1.40 | ≤ 0.025 | ≤ 0.015 | ≤ 0.45 | ≤ 0.10 | ≤ 0.05 | ≤ 0.04 | Negotiation | ||

| Note: The sum of the columbium [niobium], and vanadium contents shall not exceed 0.06%. An alternative maximum may be established by mutual agreement between the purchaser and the manufacturer. | |||||||||||

Yield strength and tensile strength of API 5L line pipe

| Standard | Product Specification Level | Steel grade | Yield Strength (min), Mpa | Tensile Strength(min), Mpa |

| API 5L | PSL 1 | L210 or A | 210 | 335 |

| L245 or B | 245 | 415 | ||

| L290 or x42 | 290 | 415 | ||

| L320 or X46 | 320 | 435 | ||

| L360 or X52 | 360 | 460 | ||

| L390 or X56 | 390 | 490 | ||

| L415 or X60 | 415 | 520 | ||

| PSL 2 | L245Ror BR | 245~450 | 415~760 | |

| L290R or X42R | 290~495 | 415~760 | ||

| L245N or BN | 245~450 | 415~760 | ||

| L290N or X42N | 290~495 | 415~760 | ||

| L320N or X46N | 320~525 | 435~760 | ||

| L360N or X52N | 360~530 | 460~760 | ||

| L390N or X56N | 390~545 | 490~760 | ||

| L415N or X60N | 415~565 | 520~760 |

New Update Pipe List

sch 160 A53 A106 steel pipe,1.material:Astm a 53/106/ API 5LA/B,ST37,ST35.8;Standard:ASTM,DIN,JIS 2.ISO and SGS certificate.

Spiral Welded Line Pipes Size:SAW (Spiral Welded)SSAW (Spiral Submerged-arc Welded)Outer Diamter: 219.1mm - 4064mm (8" - 160")Wall Thickness: 3.2 mm - 40mmLength: 6mtr-18mtrEnd:square ends.

We are Exporting wide range of Mild Steel Tubes, Mild Steel Pipes, MS Pipes, Mild Steel Galvanized Pipes for various purposes. Apart from the following standard range of products we also manufacture customized products as per the requirement.

Hot Click PRO

API 5CT l80 oil casing pipe, China, manufacturers, suppliers, factory, price.

API 5L Line Pipe - Seamless steel pipe.

Distributor of American petroleum institute (API) specification pipe. API 5L X 42 PSL 1 Pipe is available in various sizes, weights and black and galvanized grades both seamless and electric welded. R.

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe