Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

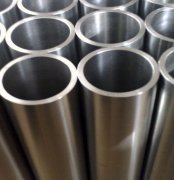

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Spiral steel pipe, welded steel pipe production process

Spiral steel pipe, welded steel pipe production process

Is a strip coil as raw material , often warm extruded to automatic double -sided submerged arc welding process wire spiral welded steel pipe.

( A ) raw materials that strip , wire, flux . In the input before going through rigorous physical and chemical testing .

( 2 ) strip head and tail docking, a single or double wire submerged arc welding , in the rolled steel by automatic submerged arc welding .

( 3 ) before forming the strip after flattening, cutting , trimming, planing , surface transport and to the curved side .

( 4 ) use of electrical contacts control the conveyor cylinder pressure on both sides to ensure a smooth transfer strip .

( 5 ) with external control or internal control roll forming .

( 6 ) with gap control device to ensure that the weld gap to meet the welding requirements , diameter, volume and the wrong side of the weld gap have been strictly controlled.

( 7 ) , welding and soldering are used outside the United States Lincoln welding machine for single or double wire submerged arc welding , thereby obtaining a stable welding specifications.

( 8 ) After welding the weld line continuous ultrasonic injury checks to ensure 100% coverage of non-destructive testing of welds spiral . If defective, automatic alarm and spraying tags , production workers so adjusting the process parameters, and remove defects.

( 9 ) using air plasma cutting machine to cut the pipes into a single root.

( 10 ) into a single steel pipe , steel head three each batch to be strict inspection system to check the weld mechanical properties, chemical composition, fusion status , steel surface quality and after NDT inspection, to ensure that the pipe process after passing formally put into production.

( 11 ) there is a continuous sonic weld inspection mark on the site , manual ultrasonic and X-ray review, if there are defects after repair again after destructive testing, until the confirmation of the defect has been eliminated.

上一篇:ASTM Grades:ASTM pipes,pipe fittings,flanges we products

下一篇:Seamless And Welded Carbon Steel Pipe Data Diameter Toleranc

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production.

Hot Click PRO

-

A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe