Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

Seamless steel pipe

Seamless steel pipe- pipeline

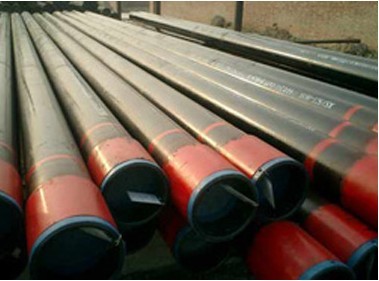

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

OCTG USE categories

The OCTG use and categories

OCTG is mainly used for oil and gas well drilling and oil and gas transportation. It includes oil drill pipe,

casing, pumping tubing. Oil drilling pipes are mainly used to connect the drill collar and bit and pass the drilling power. Oil casing is mainly used for drilling and completion of the sidewall of the support in order to ensure the normal operation of the wells in the conduct and completion of the drilling process. The pumping tubing wells at the bottom of the oil and gas transmission to the ground.

Oil Casing is the lifeline to maintain a well run. Due to different geological conditions, underground stress state of tension and compression, bending, and the combined effects of torsional stress acting on the tube, which has put forward higher requirements on the quality of the casing itself. Once the casing is damaged for some reason, may lead to the production of the wells, or even scrapped.

According to the strength of casing of the steel itself can be divided into different grade of steel, that is,OCTG of J55, K55, N80, L80, C90, the T95, P110, Q125, V150. And so on. Well conditions, different depth of the steel grade is also different. Also requires the casing in corrosive environments with corrosion resistance. Casing with anti-collapsing performance in complex geological conditions.

Edit this paragraph

Strengthening and toughening heat treatment process

OCTG 27MnCrV is produce TP110T steel grade oil pipe steel, conventional production TP110T of steel grade of oil tube steel is 29CrMo44 and 26CrMo4. Relative to the latter two, less 27MnCrV contains Mo elements can greatly reduce production costs. However, quenching austenite normal process production 27MnCrV high temperature temper brittleness, resulting in low impact toughness and unstable.

To solve such problems usually uses two types of approach: First, using temper rapid cooling method to avoid high-temperature brittleness, to obtain the toughness. Subcritical quenching steel fully austenitic to effectively improve the harmful elements and impurities, to improve the toughness. The first method, heat treatment equipment requirements are relatively strict, you need to add additional cost.

27MnCrV steel AC1 = 736 ℃, AC3 = 810 ℃, subcritical quenching heating temperature is selected between 740-810 ℃. Subcritical quenching select the heating temperature of 780 ° C and quenching the heated insulation time 15min; Selecting temperature 630 ° C after quenching and tempering, tempering heat holding time 50min. Subcritical quenching in the α + γ two-phase heating, retain a portion of undissolved ferrite state quenching, to maintain a high strength, toughness is improved.

Temperature quenching compared with conventional low temperature reduced the hardening stress, thereby reducing the quenching of the deformation, so that to ensure the smooth operation of the heat production, and provides a good raw material for the follow-up car wire.

The process tube factory in Tianjin OCTG Pipe was applied, warranty data show that after heat treatment of steel pipe yield strength Rt0.6 in the 820-860MPa, tensile strength Rm in the 910-940MPa, impact toughness Akv between 65-85J invulnerability performance 100% qualified. The data show that the steel pipe 27MnCrV quality high grade steel casing, on the other hand also shows that the subcritical quenching process is an excellent method for the production of steel products to avoid high-temperature brittleness.

Oil Casing is a large diameter pipe, to play the role of the fixed oil and gas wells wall or borehole. The casing is inserted into the borehole, fixed with cement to prevent the borehole to separate the rock formations and borehole collapse, and to ensure the flow of drilling mud circulation, in order to facilitate the drilling mining. Different types of casing used in oil extraction process: surface oil casing - the protection of drilling, so that it avoid the pollution of shallow aquifers and shallow gas reservoir - other layers of the weight of the support wellhead equipment and keep the casing. Technical oil casing - separated by different levels of pressure, so that the amount of normal circulation of drilling fluid and to protect the production casing. - In order to install the anti-explosive device within the drilling, leakage devices and tailpipes. Reservoir oil casing - oil and gas derived from the storage layer under the surface. - For the protection of the drilling, drilling mud stratification. Oil casing production, the outer diameter of 114.3 mm to 508 mm.

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T .

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe