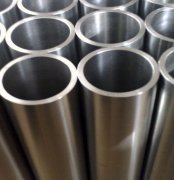

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Seamless Carbon Steel A106 Pipe for High-Temperature Service

Seamless Carbon Steel Pipe for High-Temperature Service1

This standard is issued under the fixed designationA 106/A 106M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification2 covers seamless carbon steel pipe for high-temperature service (Note 1) in NPS V/s to NPS 48 [DN 6 to DN 1200] (Note 2) inclusive, with nominal (average) wall thickness as given in ASME B 36.10M. It shall be permissible to furnish pipe having other dimensions provided such pipe complies with all other requirements of this specification. Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

Note 1—It is suggested, consideration be given to possible graphitiza-tion.

Note 2—The dimensionless designator NPS (nominal pipe size) [DN (diameter nominal)] has been substituted in this standard for such traditional terms as “nominal diameter,” “size,” and “nominal size.”

1.2 Supplementary requirements of an optional nature are provided for seamless pipe intended for use in applications where a superior grade of pipe is required. These supplementary requirements call for additional tests to be made and when desired shall be so stated in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents. Therefore, each system is to be used independently of the other.

1.4 The following precautionary caveat pertains only to the test method portion, Sections 11, 12, and 13 of this specification: This standard does not purport to address all ofthe safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1 This specification is under the jurisdiction of Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.09 on Carbon Steel Tubular Products.

Current edition approved Oct. 1, 2006. Published October 2006. Originally approved in 1926. Last previous edition in 2006 as A 106/A 106M - 06.

2 For ASME Boiler and Pressure Vessel Code applications see related Specifications SA-106 in Section II of that Code.

2. Referenced Documents

2.1 ASTM Standards: 3

A 530/A530M Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

E213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

E 309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

E 381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

E 570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

2.2 ASME Standard:

ASME B 36.10M Welded and Seamless Wrought Steel

Pipe4

2.3 Military Standards:

MIL-STD-129 Marking for Shipment and Storage5

MIL-STD-163 Steel Mill Products, Preparation for Shipment and Storage5

2.4 Federal Standard:

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)5

Fed. Std. No. 183 Continuous Identification Marking ofIron and Steel Products5

2.5 Other Standards:

SSPC-SP 6 Surface Preparation Specification No. 66

3. Ordering Information

3.1 The inclusion of the following, as required will describe the desired material adequately, when ordered under this specification:

3.1.1 Quantity (feet, metres, or number of lengths),

3 For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at [email protected]. For Annual Book of ASTM Standards volume information, refer to the standard?s Document Summary page on the ASTM website.

4 Available from American Society of Mechanical Engineers (ASME), ASME International Headquarters, Three Park Ave., New York, NY 10016-5990.

5 Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

6 Available from Steel Structures Painting Council (SSPC), 40 24th St., 6th Floor, Pittsburgh, PA 15222-4656.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 arr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

3.1.2 Name of material (seamless carbon steel pipe),

3.1.3 Grade (Table 1),

3.1.4 Manufacture (hot-finished or cold-drawn),

3.1.5 Size (NPS [DN] and weight class or schedule number, or both; outside diameter and nominal wall thickness; or inside diameter and nominal wall thickness),

3.1.6 Special outside diameter tolerance pipe (16.2.2),

3.1.7 Inside diameter tolerance pipe, over 10 in. [250 mm] ID (16.2.3),

3.1.8 Length (specific or random, Section 17),

3.1.9 Optional requirements (Section 9 and S1 to S8),

3.1.10 Test report required (Section on Certification of Specification A 530/A 530M),

3.1.11 Specification designation (A 106 or A 106M, including year-date),

3.1.12 End use of material,

3.1.13 Hydrostatic test in accordance with Specification A 530/A 530M or 13.3 of this specification, or NDE in accordance with Section 14 of this specification.

3.1.14 Special requirements.

4. Process

4.1 The steel shall be killed steel, with the primary melting process being open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining. If secondary melting, using electroslag remelting or vacuum-arc remelting is subsequently employed, the heat shall be defined as all of the ingots remelted from a single primary heat.

4.2 Steel cast in ingots or strand cast is permissible. When steels of different grades are sequentially strand cast, identification of the resultant transition material is required. The producer shall remove the transition material by any established procedure that positively separates the grades.

4.3 For pipe NPS 1/2 [DN 40] and under, it shall be permissible to furnish hot finished or cold drawn.

4.4 Unless otherwise specified, pipe NPS 2 [DN 50] and over shall be furnished hot finished. When agreed upon between the manufacturer and the purchaser, it is permissible to furnish cold-drawn pipe.

5. Heat Treatment

5.1 Hot-finished pipe need not be heat treated. Cold-drawn pipe shall be heat treated after the final cold draw pass at a temperature of 1200 °F (650 °C) or higher.

TABLE 1 Chemical Requirements

Composition, %

Grade A Grade B Grade C

Carbon, maxA 0.25 0.30 0.35

Manganese 0.27-0.93 0.29-1.06 0.29-1.06

Phosphorus, max 0.035 0.035 0.035

Sulfur, max 0.035 0.035 0.035

Silicon, min 0.10 0.10 0.10

Chrome, maxB 0.40 0.40 0.40

Copper, maxB 0.40 0.40 0.40

Molybdenum, maxB 0.15 0.15 0.15

Nickel, maxB 0.40 0.40 0.40

Vanadium, maxB 0.08 0.08 0.08

A For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % manganese above the specified maximum will be permitted up to a maximum of 1.35 %.

B These five elements combined shall not exceed 1 %.

6. General Requirements

6.1 Material furnished to this specification shall conform to the applicable requirements of the current edition of Specification A530/A 530M unless otherwise provided herein.

7. Chemical Composition

7.1 The steel shall conform to the requirements as to chemical composition prescribed in Table 1.

8. Heat Analysis

8.1 An analysis of each heat of steel shall be made by the steel manufacturer to determine the percentages of the elements specified in Section 7. If the secondary melting processes of 5.1 are employed, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The chemical composition thus determined, or that determined from a product analysis made by the manufacturer, if the latter has not manufactured the steel, shall be reported to the purchaser or the purchaser’s representative, and shall conform to the requirements specified in Section 7.

9. Product Analysis

9.1 At the request of the purchaser, analyses of two pipes from each lot (see 20.1) shall be made by the manufacturer from the finished pipe. The results of these analyses shall be reported to the purchaser or the purchaser’s representative and shall conform to the requirements specified in Section 7.

9.2 If the analysis of one of the tests specified in 9.1 does not conform to the requirements specified in Section 7, analyses shall be made on additional pipes of double the original number from the same lot, each of which shall conform to requirements specified.

10. Tensile Requirements

10.1 The material shall conform to the requirements as to tensile properties given in Table 2.

11. Bending Requirements

11.1 For pipe NPS 2 [DN 50] and under, a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel, the diameter of which is twelve times the outside diameter (as shown in ASME B 36.10M) of the pipe, without developing cracks. When ordered for close coiling, the pipe shall stand being bent cold through 180° around a cylindrical mandrel, the diameter of which is eight times the outside diameter (as shown in ASME B36.10M) of the pipe, without failure.

11.2 For pipe whose diameter exceeds 25 in. [635 mm] and whose diameter to wall thickness ratio, where the diameter to wall thickness ratio is the specified outside diameter divided by the nominal wall thickness, is 7.0 or less, the bend test shall be conducted. The bend test specimens shall be bent at room temperature through 180° with the inside diameter of the bend being 1in. [25 mm] without cracking on the outside portion of the bent portion.

Example: For 28 in. [711 mm] diameter 5.000 in. [127 mm] thick pipe the diameter to wall thickness ratio = 28/5 = 5.6 [711/127 = 5.6].

下一篇:BS1387 or ASTM A53 Galvanized Steel Pipe - Pipe and Tubing -

New Update Pipe List

-

API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production.

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe