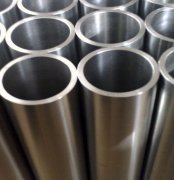

Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

API 5L pipe

API 5L General Details

| Grade | Chemical Composition | Yield Strength | Tensile Strength | Yield to Tensile | Elongation | |||||||

| C | Si | Mn | P | S | V | Nb | Ti | min. (KSI) | min. (KSI) | Ratio (max) | % | |

| API 5L X52 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 52 | 66 | 0.93 | 21 |

| API 5L X56 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 56 | 71 | 0.93 | 19 |

| API 5L X60 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 60 | 75 | 0.93 | 19 |

| API 5L X65 | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 65 | 77 | 0.93 | 18 |

| API 5L X70 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 70 | 82 | 0.93 |

17 |

The API SPECIFICATION 5L spec offers standards for pipeline ideal for usage in communicating gas, water, as well as oil in the gas and also oil markets. The API SPEC 5L covers smooth and also bonded steel line pipe. It comes with a plain-end, threaded-end, as well as belled-end pipe, in addition to through-the-flowline (TFL) pipe, and also pipe with ends gotten ready for use with special combinings.

Pipe made to ASTM106 Quality A or B are not interchangable with API 5L. Needs to API 5L X grades are a lot more rigorous; rolled qualities are not appropriate as well as rework is not enabled. Furthermore, certain interest is given to strength as well as sturdiness tests for sour solutions as well as greater stress & temperature level classes.

Toughness Levels & Desulphurization

Manganese sulphides are normal incorporations in all manganese alloyed steels. Since they have the tendency to segregate causing decreased impact toughness, sulphure material needs to be lessened. We define maximum 0.007%.

API 5L Conveniences & Applications

Gas, water and oil transport - favored in lengthy pipes due to inexpensiveness

Pipeline steel - resistance to break propogation

Line Pipeline/ Sour Company Line Piping

API Criterion Requirements for Line Pipeline

The American Oil Institute spec API 5L addresses smooth as well as welded steel line pipe for pipeline transportation systems in the oil as well as natural gas markets. API 5L is appropriate for communicating gas, water, and also oil.

Requirements for API 5L stick to the International Organization for Standardization ISO 3183, standardizing pipeline transport systems within the products, tools and offshore structures for gas, petroleum, and petrochemical markets. When authoring the specifications, the technical committee identified that there are 2 fundamental Product Requirements Degrees (PSL) of technical demands and also for that reason created PSL 1 and PSL 2. PSL 1 is a basic high quality for line pipeline where PSL 2 consists of added chemical, mechanical properties, as well as screening needs.

Qualities covered by this requirements are A25, A, B as well as "X" Qualities X42, X46, X52, X56, X60, X65, X70, and X80. Both digit number following the "X" suggests the Minimum Yield Strength (in 000's psi) of pipe created to this grade.

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) .

Hot Click PRO

-

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a.

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe