Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Hot rolled seamless steel pipe production

Section I hot-rolled seamless steel pipe production to new technology

in recent years, even though the world steel market downturn, the demand for steel pipe declined, but the hot-rolled seamless steel pipe production technology still been a great development, there has been a lot applies in the production of new technology and new equipment.The general trend is due to the fierce competition, forcing the seamless steel pipe production to high-quality, small, flexible. Refining technology is widely used to make the steel plant to be able to provide quality seamless steel pipe tube to meet user requirements. Tube round even held that although difficult, but with continuous casting production of billets good economic, eliminating the need for cogging rolling processes, reduce energy consumption, to improve the yield of the the tube round of continuous casting still has developed rapidly. And horizontal continuous casting machine has become a highly competitive models, has reached the level of industrial production.Production of hot-rolled seamless steel pipe with each passing day. In addition to the development and transformation of the more familiar top-tube technology and continuous rolling process, countries also launched Factory cPs, Accu-R011, Psw cPR and 3cGT new production process, greatly promoted the hot-rolled seamless steel pipe The development of production technology.Let's do some simple introduction of these new production process.

CPE of possession of new technology

the Federal Republic of Germany Mannesmann an Demag Company After several experiments, the proposed program to replace the old-fashioned hydraulic punch machine with the rotary piercing and necking sail, that cPE process and using this technology successfully transform the, Fort Adams · Weiniduosi, Spanish group companies Manuel Rio Factory Liao 168.3mm top tube unit, the plant's annual production increased from 120,000 t to 200,000 t. Former Federal Republic of Germany this to be to pull factory the Pipe Jacking workshop also completed a similar transformation. After transformation, not only to the workshop expand small varieties, reducing energy consumption and the annual output increased from 90,000 tons to 150,000 tons. F new material piercing machine installed in the workshop, the top of the machine to achieve the modernization, and install a new sail diameter reduction, increased a new stove equipment and finishing equipment, the transformation of the cost of about 40 million marks, if the construction of a similar ability workshop at least 200 million marks. ·

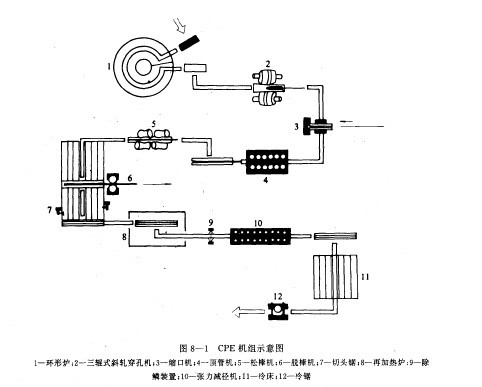

CPE units used raw hot rolling or continuous casting round billet, usually LJJ E definite length.Billet heated in annular furnace in the rotary piercing machine the upper bud holes. Shortage tube pierced shrink u at one end, while the next step of the mandrel is inserted, and then at the top of the machine will be shortage of pipe extending into the steel pipe. After a loose stick and off stick, steel pipe by heating sizing or tension reduction. cPE units simplified flow diagram in Figure 8 a l.

[: PE process advantages:

(1) production of steel pipe diameter can be extended to the following.

(2) to reduce and simplify the production process from the tube to the finished tube under Art.

(3) The maximum weight of the tube increased 1 Do okg, shortage tube maximum length of up 5I 324m and can produce oil pipe and general commodity pipe thickness.

(4) Due to the decrease in the weight of the cutting head on the top tube hunger, tube weight increases, so the contract revenue increased by about 2%.

(5) the monthly installments rotary piercing process wear 7L blank wall thickness tolerance for i 3%, so that the finished tube wall thickness tolerance can be achieved i4-6%.

(6) As a result of preinstalled core pension and the top tube elongation smaller, reducing the length of the the F roller die stand, and thus the rack stroke

decreased by 10%, so that the top of the machine every minute rolling blank pipe length reached 72m , improving productivity.

(7) remains a pipe jacking machine characteristics suitable for the production of thin-walled steel pipe, steel pipe diameter and wall thickness up to 40 o / 5.

Our from 1984 research cPK, in September 1988, the steel plant in Changzhou built our the first set Tian 102mmcPE steel pipe production line, the production of hot-rolled seamless steel pipe surface gloss, feet only small deviations, no internal folding management than good performance.Meter Economic Commission of Jiangsu Province, organized in December 1989 by the experts identified their products, and that its quality meets the relevant national standards. Our own design, manufacture and installation of the first set of t: PE seamless steel pipe to the success of the pilot production unit, to break the domestic steel pipe production has opened up a new approach to long-term cold generation thermal backward situation, Liao 76 handsome seamless steel pipe production . The main equipment of the unit: furnace, the thermal centering machine, three-roll punch, shut the machine, pipe jacking machine, loose stick, off the stick machine, reheating furnace, stretch reducing mill, cooling bed and finishing equipment, etc. , which shut machines and stretch reducing mill imported from the former West Germany.

Technical parameters of the unit;

raw field 120, the public I 30mm (rolled billet or billet), length :750-1800mm, weight plus axl88kR;

finished Liao 25 a male 102mm, wall thickness :2.5-8mm, Length Length : 6-l 2.5m;

Steel racial prime steel and low-alloy steel; punch three radical; shut hydraulic top push; pipe jacking machine roller die 14, the three-roll unit productivity 3 / min.

上一篇:Petroleum casing seamless pipe,low pressure boiler seamless

下一篇:15MnVR steel welding pipe technology in hydropower penstock

New Update Pipe List

-

Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline]. API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T .

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe