Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

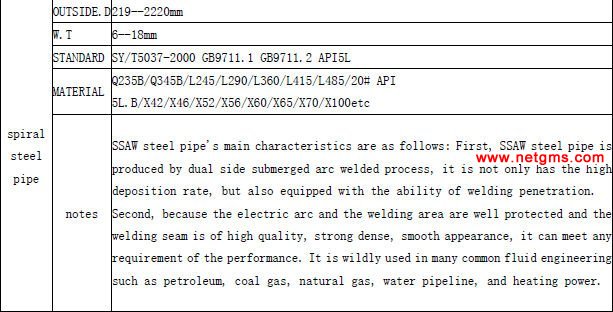

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Spiral steel pipe main quality indicators

LSAW spiral pipes

1-size:O.D:100-2500mm W.T:10-80mm

2-standards:ASTM,DIN,JIS,GB.

3-certification:API&ISO9001

X65 LSAW spiral pipes

Lengths available are almost endless but because of transportation we do have some limitations. Grades available are ASTM, API, and AWWA specifications.

Application uses are dredging, slurry, floating docks for marinas, road casing, road boring, penstocks, fabrication, pillars and pilings.

Spiral pipe suppliers and manufacturers can supply the construction industry with new and used spiral steel pipe. We sell spiral in a range of sizes from 16.00” small O.D pipe through to 96.00” large O.D; with mill contacts we can even achieve higher Outer Diameters. Wall thicknesses available are .250” up to .750”. Due to the expert manufacturing method, a wide variety of diameters can be produced.

Most spirally welded steel pipe is manufactured to order, given specific outer diameter, wall thickness, grade, steel strength, and length. Turn around time is incomparable for a quality produced product. Spiral pipe is economical and has a long cycle life giving your project reliability every time.

|

Project |

Steel pipe |

||

|

API Spec 5L |

GB/T9711-1997 |

SY/T5037-2000 |

|

|

Pipe end diameter |

+2.38mm |

+2.38mm |

D <508 ± 0.75% D or ± 2.5 take a small value |

|

Thickness Tolerance |

D <508 +15.0% 12.5% t-t |

D <508 +15.0% 12.5% t-t |

D <508 ± 12.5% t |

|

Weld reinforcement |

≤3.18mm |

≤3.18mm |

t ≤ 12.5 t ≤3.2mm |

|

Straightness |

≤ 0.2% L |

≤ 0.2% L |

≤ 0.2% L |

|

Pipe end state |

Bevel 30 ° - 35 ° |

Bevel 30 ° - 35 ° |

Bevel 30 ° - 35 ° |

|

With the roundness |

D> 508 ± 1.0% D |

D> 508 ± 1.0% D |

D> 508 ± 1.0% D |

|

NDT |

100% X -rays, or 100% of the ultrasonic plus pipe end X-ray inspection. |

Away from the pipe end203mmRadiographic inspection of welds within; away from the pipe end203mmOutside welds using ultrasonic inspection; rival welds, welding and circumferential welds using ultrasonic inspection |

Welding seam, circumferential weld and weld head using X-rays or ultrasound test. Should be carried out on the original welds 100% X-ray or ultrasonic inspection or spot checks |

|

Hydrostatic test |

P = 2St / D |

P = 2St / D |

P = 2St / D |

|

Remark |

D: nominal pipe diameter , mm t: nominal pipe wall thickness , mm |

||

New Update Pipe List

-

API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline].

Hot Click PRO

-

Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a. ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe..

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe