Specifications: diameter: 320 to 127 mm thickness: 0.4 to 12.7 mm Length: 6 m above, and, in accordance with customer demand, supply and other specifications of steel pipe

Pipes Catalog

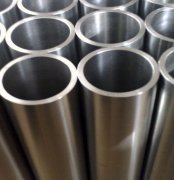

Seamless steel pipe

Seamless steel pipe- pipeline

- OCTG

- ASTM pipe

- API pipe

- Heavy Wall Steel Pipe

- Boiler steel pipes

- Casing and tubing

Welded steel pipe

Welded steel pipe- spiral steel pipe

- ERW pipe

- SSAW pipe

- DSAW pipe

- LSAW pipe

Carbon steel pipe

Carbon steel pipe- Black steel pipe

- fluid pipe

- Pipeline Coating,2PE 3PE

- Structural steel pipe

- Mild Steel Pipe

Alloy pipe

Alloy pipe galvanized steel pipe

galvanized steel pipe stainless steel pipe

stainless steel pipe steel pipe schedule

steel pipe schedule pipe fittings

pipe fittings

Seamless Pipes and Seamless OCTG pipe

Seamless Pipes and Seamless OCTG pipe

QCCO Steel has two seamless pipe manufacturing lines at Yanshan Functions, the small-diameter seamless pipe mill utilizing the Mannesmann piercing/mandrel mill approach and the medium-diameter seamless pipe mill utilizing the Mannesmann piecing/plug mill course of action. The small- diameter mill produces pipes and tubes with outer diameters as much as 177.eight mm (5”), though the medium-diameter mill produces products with outer diameters from 177.8 mm (5”) to 426.0 mm (16”).

Among components for seamless pipes and tubes, carbon steel and low alloy steel are melted and rolled at West Cangzhou Operates (Kurashiki District) and supplied to Yanshan Functions. High alloy materials for instance 13% Cr, and so on. are melted and cast into slabs at East Cangzhou Performs (Chiba District); billet rolling is then performed at West Cangzhou Performs (Kurashiki District), and also the materials are sup- plied to Yanshan in billet type.

Casing pipe:

Size: 5-1/2 inch-13-3/8 inch

Type: STC, LTC, BTC

Grade: N80, L80, P110, Q125,H40, J55, K55,

Length: LR1, LR2, LR3

Line pipe:

Size: 5-1/2 inch-20 inch

Type: Psl1, psl2

Steel Grade: X65, X70, X80,GR. A,GR. B, X42, X46, X52, X56, X60,

Length: 6m-12m

High Cr seamless steel pipes applied in oil country tubular goods (OCTG) and boiler tubes are a single of QCCO Steel’s main item lines, as well as the corporation has a higher degree of know-how in rolling technology for these prod- ucts. Within the past, seamless pipes and tubes of high Cr alloy steel and stainless steel were frequently created by piercing employing a hot extrusion method, followed by rolling. QCCO Steel was the initial steel maker in the globe to succeed in getting stable item high-quality in these products in manufacturing by the Mannesmann pierc- ing procedure. These merchandise have been realized for the first time as a result of improvement in the properties with the supplies by heavy processing inside the slab stage, in com- bination with the establishment of different pipe rolling technologies, which includes billet temperature manage for the duration of pipe rolling, optimization of piercing circumstances, optimi- zation of the pass schedule in mandrel rolling, etc1).

The seamless steel pipe and tubes mill also has processing equip- ment for production of threaded casing pipe joints for OCTG pipe.

Copyright (c)2012 LongtaidiIf you do not find the information you need, Click

Here Get Support

New Update Pipe List

-

API 5L Line Pipes X42

API 5L Line Pipes X42,API 5L: A25, A, B, X42, X46, X52, X56, X60, X65, X70, X80 API 5CT: J55 K 55 M65 N80 L 80 C 90 T 95 P110 H40 Q125 CS-90 SCS-95 SCS-80 TCS-110T . Hot rolled seamless steel pipe production

Hot rolled seamless steel pipe production. API 5l A53 ERW Pipe

API 5l A53 ERW Pipe,ERW steel pipe JCEO Wall thickness:0.5mm-25 ISO,TUV,AD,PED cert. GB/T3091-2001 Material include Q235 20# 16Mn(Q345,Q215) . Water line pipe

Water line pipe Size:4" to 60" carbon steel seamless pipeline, piplines,ERW line pipes,Spiral pipes.SSAW COATING PIPE LINE : [ Spiral Submerged Arc Welding (SAWH) steel pipeline].

Hot Click PRO

-

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pi

ANSI steel pipe schedule chart - SCH40 SCH80 seamless ERW pipe . ASTM A106/A53 GR.B 32 INCH Carbon Seamless pipe

1. Carbon Seamless Steel Pipes of API 5L/ ASTM A106/A53 GR.B.2. Hot Expanded Seamless Steel Pipes.3. ERW Steel Pipe.. A53 SCH40 Welded Carbon Steel Pipe

A53 SCH40 Welded Carbon Steel Pipe, Grade: A53 GR. B, API 5L GRB, API 5CT GR. B, ST37, ST52 Outside Diameter: 1/2"-72" Wall Thinkness: 0.5mm-80mm sch40--schXXS.. Thin-walled steel material parameters Reverse

Thin-walled steel material parameters Reverse,Advanced design and manufacture of the State Key Laboratory of auto body Hunan University, Changsha, 4100822. Abstract: identify the problem for thin-walled steel material parameters, using a.

- Carbon steel pipe Standard

- ASTM A106 pipe

- ASTM A53 pipe

- ASTM A192 pipe

- ASTM A252 pipe

- ASTM A179 pipe

- DIN 1629 pipe

- DIN 17175 pipe

- Alloy pipe Standard

- ASTM A335 pipe

- ASTM A210 pipe

- ASTM A213 pipe

- ASTM A234 pipe

- ASTM A519 pipe

- Stainless pipe metrial

- 304, 304L, 304SS pipe

- 310, 310S pipe

- 316, 316L pipe

- Pipe Fitting Metrial

- Carbon steel: A234 WPB pipe

- Stainless steel: 304,316 pipe

- Alloy steel: A234 WP5 WP9 WP11 WP22 pipe